Enumerate and Explain Different Types of Lathe Machines

Center lathe or engine lathe machine. There are three general types of lathe machines which are engine lathes turret lathes and special purpose lathes.

Lathe Machine The Ultimate Guide For Beginners

Find lathe machine including machine tools all types of lathe machine applications of lathe machines for CNC lathe machine light duty lathe machines medium duty lathe machine heavy duty lathe machine extra heavy duty lathe machine roll turning lathe machine all geared lathe machine light weight all geared lathe machine universal and high speed all geared lathe.

. Every single one of these key lathe machine parts serves a very important function that allows you to use a lathe machine for your desired purpose. The Lathe Machine is an ancient tool. Foot Switch Foot Pedals.

The milling machine lathe attachment is attachable to an existing milling machine to eliminate the need for an operator owning both a milling machine and a lathe. Live centre and dead centre. Special Purpose and.

Below is a short explanation of the common operations you use in your CNC machining project. Also you can download the whole document in a PDF format I will add the PDF download link at the bottom of this article. Typically CNC machines use special foundation for making the machine stationary so the lathe bed doesnt move or vibrate.

So how many types of Lathe machines are there. Lathe machine has been categorized into the following types. The most common methods of holding the workpiece in a lathe are between the two centres ie.

It is also used for turning the threads on locomotive wheels. Facing Facing is the first step in most lathe operations. Each of these lathes has specific applications and distinctive characteristics.

Depending on the lathe machine there are different lathe cutting operations you can undergo to get your desired shape. 9 rows According to the type of drive the lathes can be grouped as. Taper is defined as a consistent variation in diameter that results in a wedge or conical shape.

In fact no machine shop is seen without this type of lathe. These are probably the most popular among the lathe machines. The various types of machine tools are Lathe MachineDrilling MachineGrinding Machine In todays session we Classification of Machine Tools PDF Heyllo readers today I am going to discuss about the Classification of Machine Tools.

Wheel lathe is used for machining of journals and rail rods. Lathe is a machine tool which causes workpiece to revolve so that when cutting tool comes in contact with the workpiece it removes the metal in the form of chips. CNC grinding machine 5.

CNC milling machine 3. The carrier or dog is a work holding devices in lathe machine used to hold a job when it needs to be fixed between the centers. Workpiece can be held securely and rigidly on the machine tool between centres or by means of chuck.

There are 10 different types of Lathe Machine and those are. Basically the CNC controller works with an operating system software. Work or a job inserted into the hole of a carrier and then tightly fixed.

We are going to study each and every important point of these 8 different types of lathe machines. Types of Lathe Carriers. So let me give you the introduction of the lathe machine tool.

The last part for CNC lathe is foot switches. Basic Lathe Operations Lathe operation Explained. Specification of a lathe machine tool.

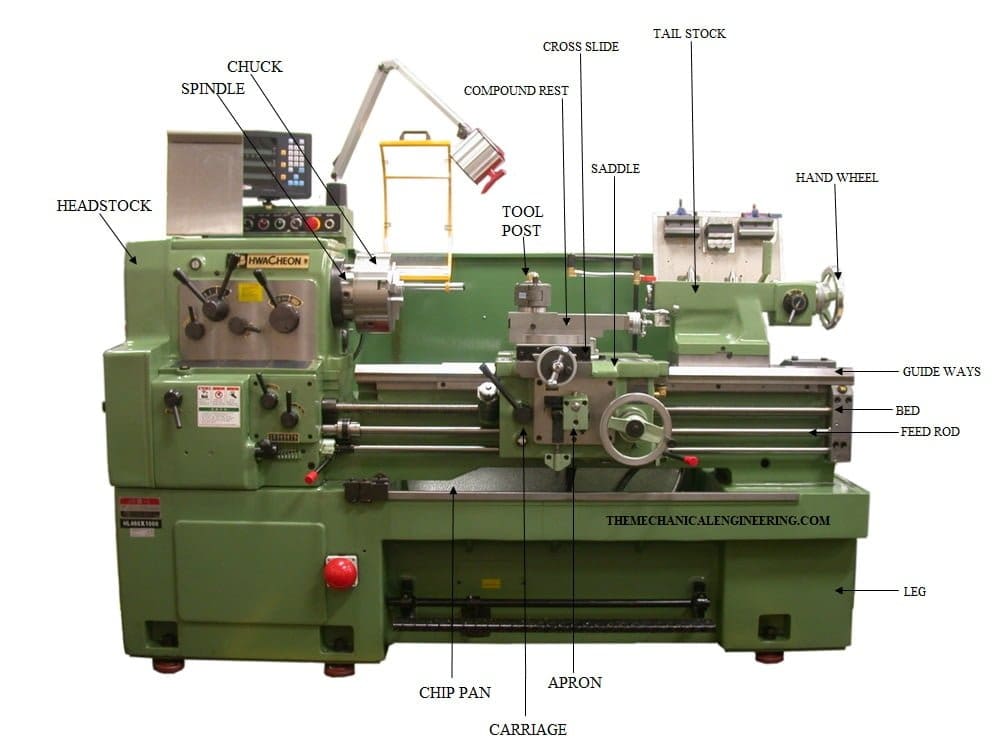

This is a type of lathe that is currently widely used and can perform operations. The bed the base the headstock for rotating the spindle the tailstock for securing your tool bit the carriage your guide the cross slide for moving your. CNC lathe machine 2.

Vertical Turret Lathe and. Common types of lathes. The high-speed lathe can also be called a wood lathe which can be operated at high speed and is.

Engine Lathe or Center Lathe. Following are the 5 different types of lathe attachments. Having step-cone pulley drive and.

Bent Tail Carrier. The workpiece of short length and large diameter of irregular shape which cannot be conveniently mounted between centres are held quickly and rigidly in a chuck. Tool Room Lathe.

Lathe machine introduction The Lathe was invented by Jacques de Vaucanson around 1751. CNC drilling machine 4. Center or Engine Lathe.

Often the following types of lathe carriers are used. Its the bottom of the lathe machine. Capstan and turret lathe.

Machine tools are those machines that make machines and products for industrial purposes. Gap bed lathe is used to machine large diameter work piece ie. It is designed to be mounted to the side of the milling machine and to be used without disturbing a setup in the associated vise.

T-shape lathe are used to machine rotors used in jet engines and gas turbines. The lathe machine operations are classified into three main categories and are as follows. Capstan and Turret Lathe.

Types of Lathe Machine Operations. Plain or Straight Turning. Up to 15 to 2 meters and 6-8 meters in length.

Following are types of CNC machine. A Lathe chuck is one of the most important devices in the lathe machine it is used for holding and rotating a piece of work while performing a lathe operation. What are the different types of tapers.

The three most popular techniques for taper turning on the lathe are the offset tailstock set-over method the compound rest method and the taper attachment method. Following are the Lathe machine operations done either by holding the workpiece between centres or by a chuck. The eight primary parts that make up a lathe machine include.

Lathe Machine Definition Parts Types Operation Specification Advantages Application Notes Pdf

Do You Know What Are The Different Types Of Lathe Machine Machine Future Machinery Future Machine Tool Industry All In Here

0 Response to "Enumerate and Explain Different Types of Lathe Machines"

Post a Comment